Headquarters

175 S Main St Suite 1310,

Salt Lake City, UT 84111

Shopify retailers are committed to providing exceptional customer experiences and they invest significantly in optimizing the customer's purchasing journey. One key strategy omnichannel retailers employ is the "Ship from Store" approach, where products are shipped directly from physical stores to customers. This strategy is favored for its potential to expedite deliveries and enhance the overall customer journey.

However, retailers adopting Ship from Store strategy often grapple with a critical issue: overselling, which occurs when retailers sell more products online than they have in stock in-store due to inventory discrepancies. This can result in order cancellations, revenue losses, and reputation damage. Moreover, challenges such as damaged items, inventory theft, reception errors, processing mistakes, and misplaced inventory add complexity to effective retail store inventory management.

To ensure that retailers don’t promise inventory that cannot be fulfilled from their stores and result in overselling, it's imperative to have a robust retail store inventory management strategy. In this blog, we will explore retail store inventory management strategies that retailers should adopt to ensure they don't promise inventory they are unable to fulfill from their stores.

Sometimes store managers refuse online orders that are sent to their store because of inventory discrepancies or because they want to keep limited items available for their in-store customers. To avoid this, store managers must reserve some inventory in their stores to prevent online order rejections. This reserved inventory is known as Safety Stock.

Retailers use safety stock to prevent stockouts or overselling in various ways. Primarily, it helps in mitigating unforeseen fluctuations in demand. For instance, if there is a sudden surge in online demand for "cargo jeans," the store will still have some inventory in stock for walk-in customers.

Further, safety stock allows retailers to mitigate the risk of inventory discrepancies by allowing them to use their reserved inventory in place of damaged, lost, or otherwise deteriorated inventory.

The amount of safety stock a retailer should maintain varies based on several factors, including the type of product, its demand, and the retailer's inventory policies. Safety stock plays a crucial role in retail store inventory management, helping retailers prevent overselling and ensuring a positive shopping experience for their customers.

For instance, let us consider a scenario where there's a high in-store demand for cargo jeans at Times Square. Retailers would want their retail store inventory management strategy on-point to ensure that sufficient inventory is on hand for walk-in customers and not allocated to Shopify. In such a case, the store manager might decide to set aside 5 cargo jeans as safety stock at the store level.

Here's the breakdown:

Total Inventory for cargo jeans at Times Square: 70

Safety Stock: 5

Inventory Available for online orders = Total Inventory - Safety Stock

= 70 - 5

= 65

Store Managers frequently notice discrepancies between the system's recorded inventory and the actual physical stock on hand. To address these discrepancies, it's essential to conduct regular inventory cycle counts. An inventory cycle count involves counting a select subset of items periodically, rather than counting the entire inventory all at once, as done in a full physical inventory count. This method is more efficient because it spreads the counting process over time, eliminating the need to count all items simultaneously. As a result, inventory cycle counting not only saves time and resources but also minimizes disruptions to daily business operations.

Performing an inventory cycle count can enhance the accuracy of a retailer's inventory records and reveal any discrepancies in stock. To carry out this process, retailers require a cycle count application that not only allows them to adjust inventory but also permits store associates to record the reasons behind any inventory variances.

Despite setting aside safety stock, retailers can still encounter the problem of overselling. Often, this arises from inadequate safety stock planning by store managers. To mitigate this risk, retailers should consider reducing the amount of inventory they declare available at the company level before allocating any to their online sales channels. This preemptive reduction in available inventory is known as the Inventory Threshold.

The Threshold count is set by the retailer and can vary based on the product category. In retail store inventory management, to determine the inventory threshold, retailers should estimate the potential inventory discrepancies. This can be done by analyzing historical data or conducting a physical inventory count across all stores. After identifying the extent of inventory inaccuracy, retailers can then adjust the threshold accordingly, minimizing the risk of overselling.

For instance, after analyzing the historical order rejection rate, a retailer determines that there's a 10% inventory inaccuracy for cargo jeans. This implies that out of every 100 cargo jeans in stock, 10 might be unavailable due to various reasons. To account for this, the retailer sets aside 10 units as the threshold for cargo jeans.

Let's break down the inventory for cargo jeans available at two locations - Times Square and Brooklyn:

Total Inventory for cargo jeans at Times Square: 70

Total Inventory for cargo jeans at Brooklyn: 30

Inventory Threshold: 10

To calculate the inventory available for online orders:

Inventory Available for online orders = (Inventory at Times Square + Inventory at Brooklyn) - Threshold

= (70 + 30) - 10

= 90

Stores occasionally face challenges in fulfilling online orders due to various reasons, including:

Insufficient Labor: A facility might not have adequate staff to handle online orders.

Natural or Man-made Disasters: A facility could be compromised or damaged due to events like earthquakes, floods, fires, or other incidents.

Holidays: During peak holiday seasons, store associates prioritize in-store sales, which might affect the processing of online orders.

Store operation managers must consider excluding the inventory of affected facilities before allocating inventory to platforms like Shopify. When the store is once again capable of fulfilling online orders, its inventory can be reintegrated and made available on Shopify.

For instance, if the Brooklyn store becomes incapacitated for any reason and can't fulfill online orders, the available inventory for online orders would be reduced to the stock from the Times Square store, which is 70 units.

Retailers on Shopify must accurately compute the available-to-promise (ATP) inventory, taking into account factors such as Safety Stock and Thresholds. Additionally, these should be excluded from the ATP calculation:

Inventory Reserved for Existing Orders: Any inventory that has already been earmarked for orders received should be subtracted from the ATP, ensuring that the same stock isn't promised twice.

Inventory from Unavailable Locations: Stock from locations that are temporarily unable to fulfill orders due to unforeseen circumstances should also be excluded from the ATP.

By considering these factors, retailers can minimize the risk of overselling and maintain a reliable retail store inventory management system on Shopify. Consider the following example:

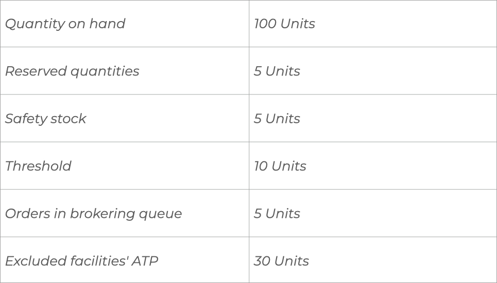

For NotNaked brand's "cargo jeans," there's a Quantity on Hand (QOH) of 100 units. Out of these, 10 units have been ordered, with 5 units already allocated for sales orders. The retailer has set an inventory threshold of 10 units for this product. Building on our previous scenario, the Brooklyn store is currently not fulfilling orders, while the Times Square location has reserved 5 units as safety stock.

To determine the Available-to-Promise (ATP) inventory, we use the subsequent formula:

ATP = QOH - (Reserved quantities + Safety stock + Threshold + Orders in brokering queue + Excluded facilities’ ATP)

Given:

ATP = 100 - (5 + 5 + 10 + 5 + 30)

= 100 - 55 = 45

Therefore, 45 units should be available as sellable inventory for online orders.

* * *

Manually managing inventory rules and determining ATP for an entire product range can be a daunting task for retailers. Recognizing this challenge, HotWax Commerce offers a solution that simplifies the process. Retailers can effortlessly set thresholds and safety stock levels for their products, ensuring that inventory discrepancies are accounted for. Additionally, they have the flexibility to toggle fulfillment on or off as needed, optimizing facility-level order processing.

The Inventory Cycle Count App, another feature from HotWax Commerce, empowers store associates to promptly record any inventory variances, ensuring that stock records remain accurate and up-to-date.

Before updating the Available to Promise Inventory on Shopify, HotWax Commerce meticulously verifies all exclusion criteria. This rigorous check ensures that retailers only commit to inventory they genuinely have on hand. The result? A significant reduction in overselling and order rejections, leading to heightened customer satisfaction.

If you are interested in learning how our retail store inventory management solution can take your brand to the next level, contact the HotWax Commerce team for a free consultation today.